Precision and Expertise: How Elite Carpet and Tile Care Restored a Custom Limestone Table

In the heart of Napa Valley, where luxury and craftsmanship meet, Elite Carpet and Tile Care has built a reputation for excellence in stone care and restoration. Led by Tony Saiz, a dedicated AntiEtch® applicator serving Santa Rosa and Napa Valley, the company recently undertook a unique and complex project—restoring and protecting a custom limestone table for Jackson Family Wines.

The Challenge: A Custom Limestone Table with V-Grooves

Jackson Family Wines, known for their exquisite estates, reached out to Tony with a challenge: a six-foot round limestone table with a distinct V-groove pattern. The table, brand new, required a protective solution that would preserve its beauty while preventing etching and staining. Traditional sealing methods were not ideal due to the intricacies of the grooved design.

Innovative Problem-Solving

Understanding the complexity of the project, Tony took a methodical approach. Rather than experimenting directly on the valuable table, he collaborated with a local fabrication shop to create a test piece—a 24-inch by 24-inch limestone sample with similar grooves.

By testing various applications, Tony identified a way to apply AntiEtch® while preserving the table’s intricate grooves. His process involved:

- Testing and Prototyping – Tony filled some grooves and left others open, experimenting with techniques to determine the best application method.

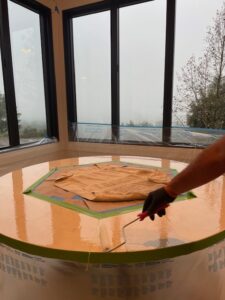

- Precision Coating – Using an artist’s paintbrush, he applied a thin layer of AntiEtch® within the grooves, then carefully dabbed it out with a foam brush for even coverage.

- Refining the Technique – After initial testing, Tony improved his method by using an eighth-inch-wide pinstripe tape to mask the grooves, ensuring crisp, clean edges.

- Controlled Curing – He lightly tacked the acrylic coating before removing the tape, preventing over-curing and ensuring a seamless application.

Executing the Project with Expert Precision

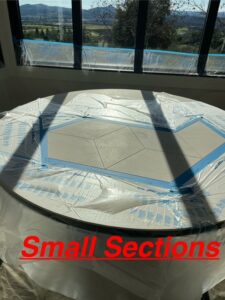

Once the testing was successful, Tony moved on to the actual table. Given the table’s size, he applied AntiEtch® in sections to maintain control over the curing process. The steps included:

- Surface Preparation – Thoroughly cleaning and sanding the limestone to create an optimal bonding surface.

An angled view of the limestone table during restoration, showing the resin filling the natural holes with UV-resistant adhesive. This critical step ensured a smooth, durable surface while preserving the table’s original beauty.

- Sectioned Application – Dividing the table into manageable sections, masking off the grooves, and applying AntiEtch® precisely.

- UV Curing & Protection – Using UV light to cure each section while protecting the already-treated areas from overexposure.

- Detail Work & Finishing – Removing any residue, refining the grooves with nail files, and achieving a flawless satin finish that seamlessly blended with the table’s original look.

A Stunning Result & Industry Recognition

The final result was a beautifully restored and protected table, with its signature grooves left intact and fully shielded from etching and stains. Jackson Family Wines was thrilled with the outcome, and the project’s success did not go unnoticed—Tony received recognition from More® at a recent industry summit for his innovation and craftsmanship.

Elite Carpet and Tile Care: The Trusted AntiEtch® Expert in Napa Valley

Tony’s meticulous planning, attention to detail, and willingness to develop new techniques set Elite Carpet and Tile Care apart in the world of stone restoration. Whether it’s protecting delicate marble surfaces or tackling complex custom projects, Tony brings a level of expertise that few can match.

For homeowners, wineries, and businesses in Napa Valley looking for premium stone care solutions, Elite Carpet and Tile Care is the trusted name in AntiEtch® applications.

Learn more about their services here or call Tony directly at 707-583-6569 to discuss your project today!

Frequently Asked Questions

What is AntiEtch®?

AntiEtch® is a revolutionary protective coating that prevents staining and etching on natural stone surfaces like marble, limestone, and onyx.

Can AntiEtch® be applied to grooved surfaces?

Yes! As demonstrated in this project, AntiEtch® can be applied with specialized techniques to protect grooved surfaces without altering their unique design.

How long does the AntiEtch® application process take?

It depends on the size and complexity of the surface. This particular project took multiple days due to its intricate details, but a standard countertop application can often be completed in a single day.

Does AntiEtch® change the appearance of my stone?

No, AntiEtch® is available in matte, satin, or polished finishes to match the original look of your stone.

Where can I find an AntiEtch® applicator near me?

If you’re in Napa Valley or Santa Rosa and surrounding areas, Elite Carpet and Tile Care is the premier certified applicator. If you’re outside the area, you can find a certified professional through the Sureshine Service Network.